2020 INDEPENDent Hip’ing study

SUBSCRIBE NOW to receive our HIP’ing independent study series.

introduction

The technology of Hot Isostatic Pressing (HIP’ing) has been around for decades and was used to consolidate powder particles together to produce powder metallurgy components. Later this technology was utilized to consolidate porosity in investment casting. Investment castings have typical replaced many components fabricated by the powder metallurgy (PM) route.

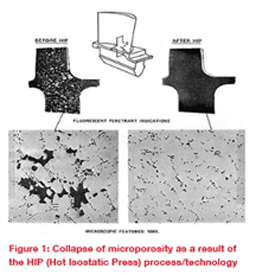

Figure 1 shows a microstructure (left hand side) of an investment cast component exhibiting high or unacceptable porosity and the same figure shows a microstructure (right hand side) of the absence/collapse of the micro pores as a result of the HIP’ing process, which is performed at high temperatures (e.g. 2150—2250°F) at high argon pressures of 15ksi – 25ksi and for 2 – 4 hours for Nickel base superalloy material.